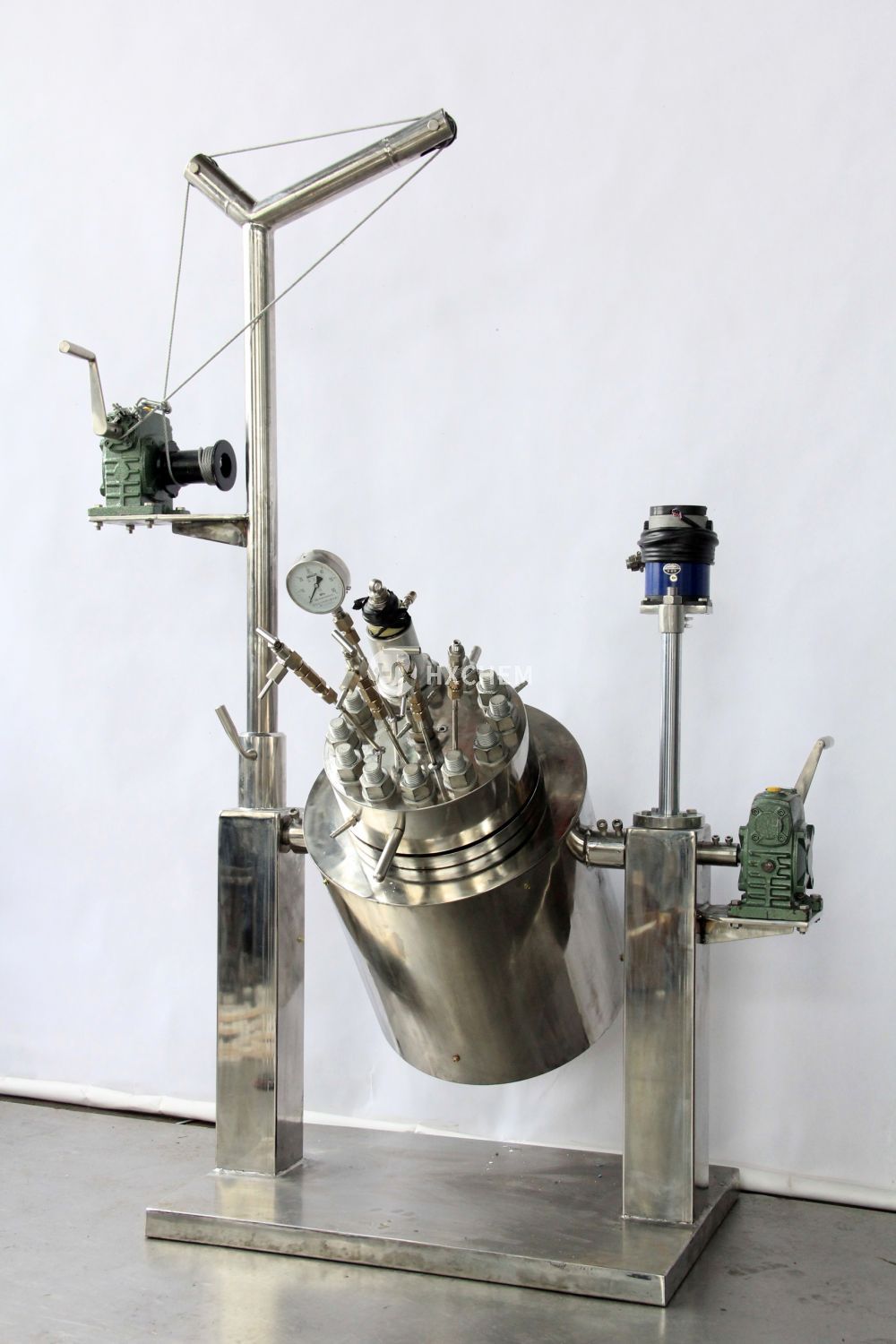

Labor-Druckreaktoren mit manuellem Deckelanheben

100 ml/ 250 ml/500 ml/1 Liter/2 Liter/5 Liter Labor-Druckreaktoren mit manuellem Heben der Abdeckung/ Labor-Druckreaktor/ Labor-Rührdruckreaktoren/ Hochdruck-Laborreaktoren/ Bodenständer-Druckreaktoren/ Rührdruckreaktoren/ Druckreaktoren mit Schraubverschluss Standard 100bar,Standard 350℃ Material:SS304/SS316, Titan,hastelloy,PTFE-Liner. Manuelle Hubdruckautoklaven | Anwendung: Chemische Entwicklung; Hochdruckanwendung ohne Leckage Korrosionstest und Katalysatortest;

- HXCHEM

- China

- 15 Tage nach Zahlung

- 40 Sätze/Monat

Einzelheiten

Manometer, Thermoelement, zentraler Rühranschluss

Flüssigkeitseinlass/Probenahmeanschluss mit Nadelventil und Tauchrohr

und Gaseinlass mit Nadelventil

Spule (optional); Solides Futterplus

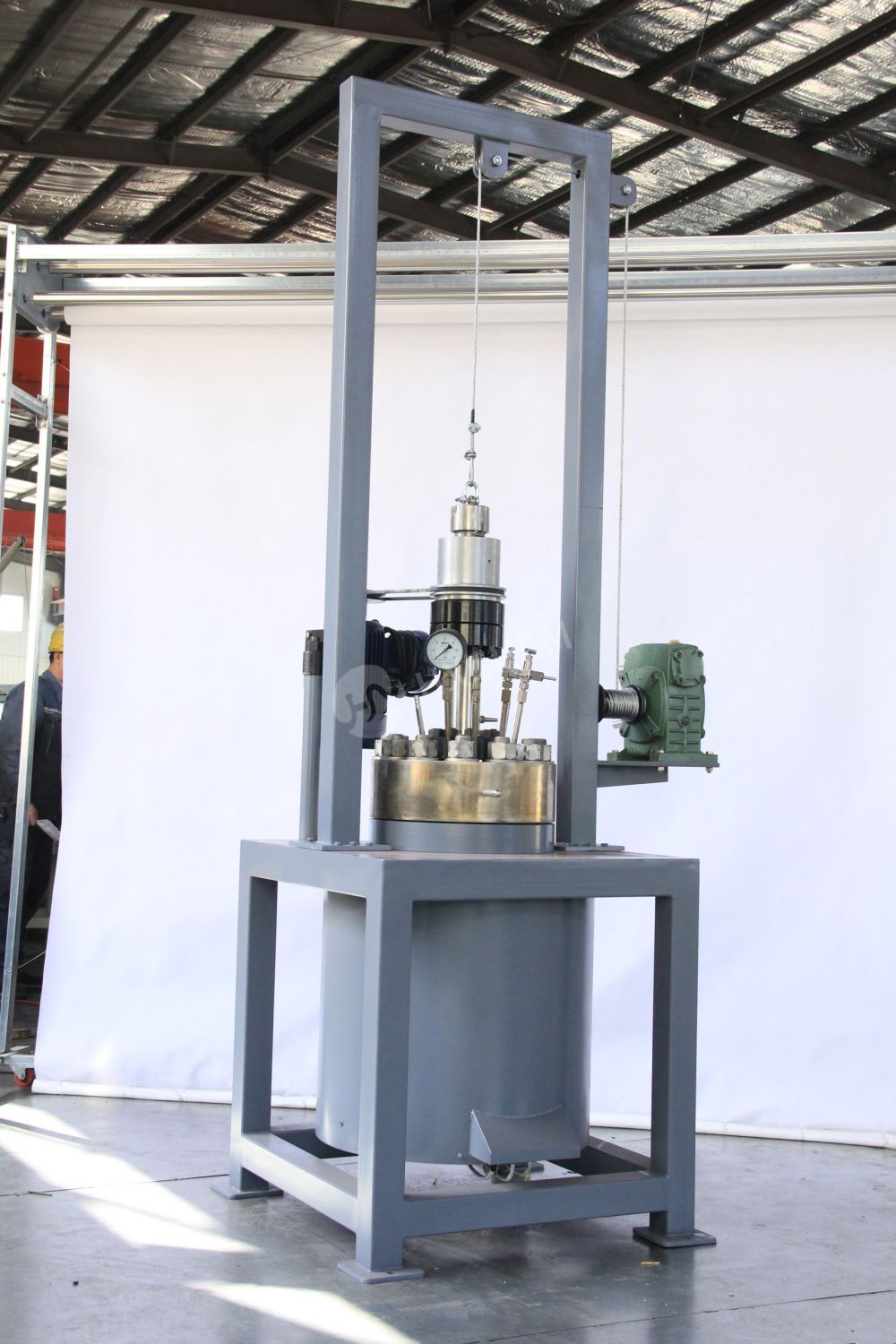

BODENSTÄNDER-DRUCKREAKTOR | Lab pressure reactors | Lab pressure autoclaves | stirred pressure reactors

Manual lifting Top cover lid & magnetic agitator can be manual lifting & lowering. Vessel body can be manual move outside for weighing;

Product Features

Lab high pressure reactor autoclaves with manual lift

100ml to 5 liters volume;

Pressure up to 100bar;

Temperature up to 350℃;

Standard materials:SS-304, SS-316, other alloys, PTFE, PPL liner, etc.

Pressure gauge display and temperature sensor.

Internal cooling coils with water tap;

Control panel with program PID temperature controller.

Gas/liquid inlet & outlet with needle valve control, dip tube, etc;

Electric heating furnace is fixed on the moveable frameplate;

Vessel body can be manual move outside for weighing;

Top cover lid & magnetic agitator can be manual lifting & lowering

Standard specfications

GSH pressure reactor standard specification table.

| Model No. | GSH-0.1 | GSH-0.25 | GSH-0.5 | GSH-1 | GSH-2 | GSH-5 |

| Nominal Capacity | 100ml | 250ml | 500ml | 1liters | 2liters | 5liters |

| Max Working Pressure | Standard 100bar; Max pressure up to 350bar | |||||

| Working Temperature | Standard 350°C;Up to 500°C | |||||

| Stirring Speed | 0-1500rpm | |||||

| Motor Power | 150W | 150W | 150W | 0.2KW | 0.2KW | 0.6KW |

| Heating Power | 1KW | 1KW | 1KW | 2KW | 2KW | 4KW |

| Closure | Flange bolts closure/ Clamp closure | |||||

Lifting & lowering (Optional) | Cover lid lifting, Vessel fixed Cover lid manual lifting, Vessel rotation Vessel lifting & lowering, vessel rotation Manual; Electric driven; Pneumatic; Hydraulic (Driven method) | |||||

| Material | SS304,SS316 or other alloys(Titanium, hastelloy, Inconel, Nickel, etc) | |||||

| Heating Method | Standard Electric heating ( Jacket heating, far infrared heating optional ) | |||||

| Cooling | Internal spiral coils(optional) | |||||

| Charging Method | Up discharge by pressure or discharge by bottom valve | |||||

| Stirring type | Propeller, paddle type, turbine, anchor type, gas induction, helix type, etc. | |||||

| Control panel | Temp.display and control, accuracy+ 1℃, Stirring speed display & control Touch screen program control(Optional) | |||||

| Standard fittings | Pressure Gage, Thermocouple, Central stirring port Liquid inlet/ Sampling port with needle valve & dip tube and gas inlet with needle valve Safety Rupture Disc: Internal cooling Coil(Optional); Solid feeding plug(Optional) | |||||

Related product

BENCH SCALE PRESSURE REACTOR

FLOOR STAND PRESSURE REACTOR

MECHANICAL/ ELECTRIC LIFTING PRESSURE REACTOR